Pug

Mill Conditioner |

| |

|

| |

|

| |

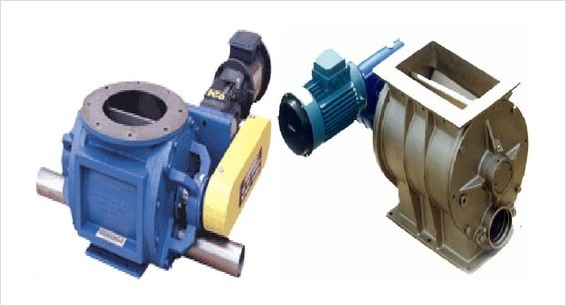

| The DIGIDALE upgraded

pugmill-designed specifically for high calcium Fly ash

applications enables the continuous silo unloading of

fly ash while minimizing fugitive dust. |

| |

| Features - |

- Precisely controlled and evenly

distributed moisture addition

- Efficient mixing and continuous

throughput using proven paddle design

- Hinged, counterbalanced top lid

with inspection door and hinged inlet and outlet

doors to improve access

- Externally mounted nozzles and

water supply manifolds for improved access and

maintenance

- Superior Wetting System Design

|

| Optimal mix of water |

| |

| The amount of water supplied to the spray nozzles is

critical, so it is controlled by a flow regulating valve

for finite adjustment of water supplied to the vessel.

The amount of water can be adjusted in relation to the

ash feed. Throughout the conditioning process, The

wetting system includes externally mounted spray nozzles

that inject a fine mist of precisely controlled water

into the mixing area of the pugmill. |

| |

| Isolation curtain to contain fugitive dust |

| |

| In addition to the water control, an isolation

curtain compartmentalizes the inlet section from the

mixing area to contain fugitive dust in the mixing area. |

| |

| Unique nozzle arrangement |

| |

| Our pug mill's unique nozzle

arrangement allows for proper water distribution inside

the mixing chamber for conditioning the ash |

| |